The store will not work correctly in the case when cookies are disabled.

JavaScript seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Javascript in your browser.

Important: The information presented here is for the use of a qualified, experienced technician. Without the background knowledge which comes with training, you risk doing more damage then good to the copier & also risk your own safety. If you are not willing to take 100% responsibility for your actions, do not use the information posted here. Thank you. Read our conditions of Use for more information.

4110 style - UI Touch Panel Replacement Instructions

4110 style - UI Touch Panel Replacement Instructions

Technical Specifications

4110 style

WorkCentre 4110/4112/4590,

D95/D110/D125/D136

Touch Panel (4110TP) Installation

CRITICAL NOTE #1 : Pay attention to which screws go where. Missing screws (particularly the machine-thread screws) can cause poor grounding of some of the components and will cause failures.

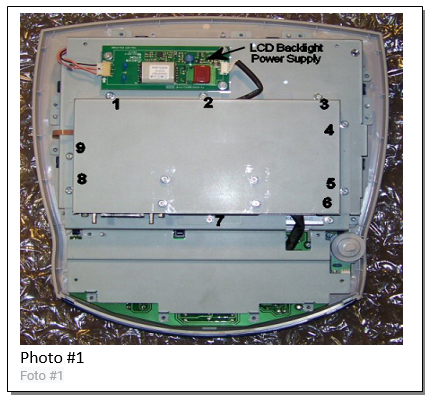

First remove the rear cover. Next remove the metal cover plate (9 machine-thread screws… see Photo #1 below)

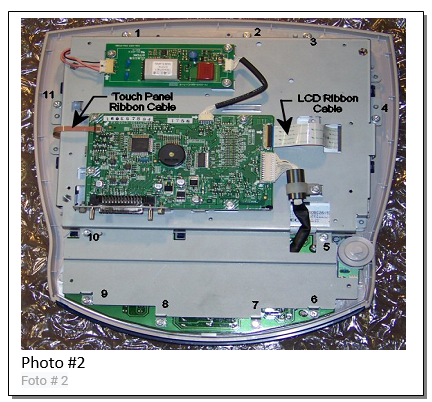

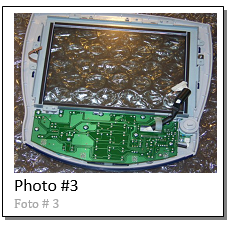

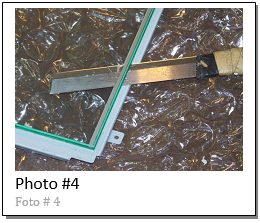

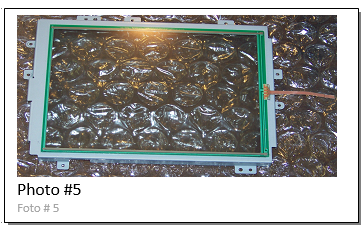

Now remove the LCD Panel Assembly (disconnect the Ribbon Cables and the connector and 4 screws). (See Photo #2 below) CRITICAL NOTE #2: The ribbon cable connectors have tiny “latches” which hold the ribbon in place. You need to lift each latch gently with a thumb nail before removing or installing a ribbon cable or you may damage the new ribbon cable.With the LCD Panel off, you can see and remove the Touch Panel Assembly (see Photo #3). You will need to remove the old touch panel glass from its metal frame completely. CRITICAL NOTE #3: It is important to remove ALL Finally you can peel off the backing of the double sided tape on the new glass. Look at how the glass sits on the metal frame to make sure you put it in the correct position. (see Photo #5).

CRITICAL NOTE #4: On the 76xx and 77xx models only, a touch problem has been reported to sometimes be caused by software issues. Reloading firmware for the UI is said to solve problems in those cases.

CALIBRATING THE TOUCH PANEL:

If the touch buttons seem to be “off” a-ways, you can recalibrate the touch panel like this: Power off the machine, then hold down the ‘1,0, & 3’ buttons together while powering back on. A calibration screen will show up. Use stylus to touch the 9 points labeled P1 through P9. The screen will change to a grid with intersecting lines. Touch the points where the lines cross in random order to see that the panel responds right.

Then turn the power off, wait a full 60 seconds and turn it back on.

Information Reference

Author: Britt Horvat, with special thanks to Kurt for his expertise and thanks also for support from whole Partsdrop gang. Originally published as an Article in the marvelous ENX Magazine - www.enxmag.com :)

All rights reserved... you can distribute copies as long as you include a link to the source website: www.partsdrop.com

Choose Model

All Models

4 (DocuColor 4)

12 (DocuColor 12)

12 (FaxCentre F12)

15 (M15)

15i (M15i)

16 (PE16)

16 (Pro-16)

16fx (Pro-16fx)

16i (PE16i)

16p (Pro-16p)

20 (C20)

20 (M20)

20i (M20i)

21 (Bookmark 21)

23 (XC23)

23 (XDL23)

24 (DocuPrint N24)

24 (WorkCentre M24)

32 (C32)

32 (DocuPrint N32)

32 (WorkCentre Pro32)

33 (XC33)

33 (XDL33)

33D (XC33D)

33D (XDL33D)

35 (Bookmark 35)

35 (CopyCentre C35)

35 (WorkCentre M35)

35 (WorkCentre Pro-35)

40 (Bookmark 40)

40 (C40)

40 (DocuPrint N40)

40 (WorkCentre Pro-40)

45 (CopyCentre C45)

45 (WorkCentre M45)

45 (WorkCentre Pro-45)

50 (DCCS-50)

55 (Bookmark 55)

55 (CopyCentre C55)

55 (WorkCentre M55)

55 (WorkCentre Pro-55)

60 (Color C60)

60 (XE60)

62 (XE62)

64 (XE64)

65 (CopyCentre C65)

65 (DocuPrint 65)

65 (DocuTech 65)

65 (WorkCentre Pro-65)

70 (Color C70)

75 (Color C75 Press)

75 (CopyCentre C75)

75 (DocuPrint 75)

75 (DocuTech 75)

75 (J75 Press)

75 (WorkCentre Pro-75)

80 (XE80)

80 (Versant 80)

82 (XE82)

84 (XE84)

88 (XE88)

90 (CopyCentre C90)

90 (DocuPrint 90)

90 (WorkCentre Pro-90)

90 (WorkCentre XE90 / XE90fx)

90fx (XE90fx)

B7025 (VersaLink)

B7030 (VersaLink)

B7035 (VersaLink)

B7125 (VersaLink)

B7130 (VersaLink)

B7135 (VersaLink)

B9100(PrimeLink)

B9110(PrimeLink)

B9125(PrimeLink)

B9136(PrimeLink)

7025 (VersaLink C7025)

C7120 (VersaLink C7120)

C7125 (VersaLink)

C7130 (VersaLink)

C8030

C-8030

C8035

C-8035

C8045

C-8045

C8055

C-8055

C8070

C-8070

C9065(PrimeLink)

C9070(PrimeLink)

100 (WorkCentre XD100)

100 (DocuTech 180)

100 (Nuvera 100)

102 (WorkCentre XD102)

103 (WorkCentre XD103)

103f (WorkCentre XD103f)

104 (WorkCentre XD104)

105 (WorkCentre XD105)

105f (WorkCentre XD105f)

118 (CopyCentre C118)

118 (WorkCentre M118)

120 (PE120)

120 (WorkCentre XD120)

120 (DocuTech 120)

120f (WorkCentre XD120f)

120i (PE120i)

120 (Nuvera 120)

123 (CopyCentre C123)

123 (WorkCentre M123)

123 (WorkCentre Pro123)

125 (WorkCentre XD125)

125f (WorkCentre XD125f)

128 (CopyCentre C128)

128 (DocuTech 128)

128 (WorkCentre M128)

128 (WorkCentre Pro128)

130 (WorkCentre XD130)

130 (WorkCentre XD130df)

133 (CopyCentre C133)

133 (WorkCentre M133)

133 (WorkCentre Pro133)

135 (DocuTech 135)

144 (Nuvera 144)

155 (WorkCentre XD155)

155 (WorkCentre XD155df)

155 (DocuTech 155)

165 (CopyCentre 165)

165 (WorkCentre 165)

175 (CopyCentre 175)

175 (WorkCentre 175)

180 (DocuTech 180)

180 (Versant 180)

200 (Nuvera 200)

212 (DocumentCentre 212)

214 (DocumentCentre 214)

215 (Pro215)

220 (DocumentCentre 220)

230 (DocumentCentre 230)

232 (CopyCentre 232)

232 (WorkCentre Pro-232)

232 (WorkCentre 232)

238 (CopyCentre 238)

238 (WorkCentre Pro-238)

238 (WorkCentre 238)

240 (DocuColor 240)

240 (DocumentCentre 240)

242 (DocuColor 242)

245 (CopyCentre 245)

245 (WorkCentre 245)

245 (WorkCentre Pro-245)

250 (DocuColor 250)

252 (DocuColor 252)

255 (CopyCentre 255)

255 (DocumentCentre 255)

255 (WorkCentre 255)

255 (WorkCentre Pro-255)

260 (DocuColor 260)

265 (CopyCentre 265)

265 (DocumentCentre 265)

265 (WorkCentre 265)

265 (WorkCentre Pro-265)

275 (CopyCentre 275)

275 (WorkCentre 275)

275 (WorkCentre Pro-275)

288 (Nuvera 288)

312 (WorkCentre 312)

315 (WorkCentre Pro-315)

332 (DocumentCentre 332)

340 (DocumentCentre 340)

351 (XC351)

355 (XC355)

356 (XC356)

385 (WorkCentre 385)

395 (WorkCentre 395)

412 (WorkCentre Pro412)

415 (WorkCentre Pro415)

416 (WorkCentre Pro416)

420 (DocumentCentre 420)

420 (WorkCentre Pro420)

421 (WorkCentre Pro421)

423 (WorkCentre Pro423)

425 (DocumentCentre 425)

426 (DocumentCentre 426)

428 (WorkCentre Pro428)

430 (DocumentCentre 430)

432 (DocumentCentre 432)

440 (DocumentCentre 440)

460 (DocumentCentre 460)

470 (DocumentCentre 470)

480 (DocumentCentre 480)

490 (DocumentCentre 490)

510dp (Engineering Printer)

520 (XC520)

535 (DocumentCentre 535)

535 (WorkCentre Pro-535)

545 (DocumentCentre 545)

545 (WorkCentre Pro-545)

550 (Color 550)

555 (DocumentCentre 555)

560 (Color 560)

570 (Color 570)

580 (XC580)

635 (WorkCentre Pro635)

645 (WorkCentre Pro645)

657 (WorkCentre Pro657)

665 (WorkCentre Pro665)

685 (WorkCentre Pro685)

700 (Digital Color Press 700)

700i (Digital Color Press 700i)

735 (WorkCentre Pro735)

745 (WorkCentre Pro745)

765 (WorkCentre Pro765)

770 (Digital Color Press 770)

780 (Phaser 780)

785 (WorkCentre Pro785)

790 (Phaser 790)

810 (XC810)

811 (XC811)

820 (XC820)

830 (XC830)

855 (XC855)

865 (XC865)

875 (XC875)

WC-3215

WC-3225

WC-3335

WC-3345

1012 (Vintage Analog Copier)

1020 (Antique Copier)

1020 (XC1020)

1025 (Vintage Analog Copier)

1033 (XC1033)

1035 (Vintage Analog Copier)

1038 (Vintage Analog Copier)

1040 (Vintage Analog Copier)

1040 (XC1040)

1044 (XC1044)

1045 (Vintage Analog Copier)

1045 (XC1045)

1048 (Vintage Analog Copier)

1050 (Vintage Analog Copier)

1065 (Vintage Analog Copier)

1075 (Vintage Analog Copier)

1090 (Vintage Analog Copier)

1245 (XC1245)

1250 (XC1250)

1255 (XC1255)

1632 (DocuColor 1632)

1875 (XC1875)

2006 (DocuColor 2006)

2045 (DocuColor 2045)

2060 (DocuColor 2060)

2100 (Versant 2100)

2120 (XL2120)

2128 (C2128)

2130 (XL2130)

2130 (XL2130f)

2140 (XL2140)

2140 (XL2140df)

2218 (FaxCentre 2218)

2240 (DocuColor 2240)

2510 (Engineering Copier)

2515 (Engineering Copier)

2520 (Engineering Copier)

2600 (Antique Copier)

2636 (C2636)

2675 (XC2675)

2830 (Antique Copier)

3001 (Engineering Copier)

3030 (Engineering Copier)

3040 (Engineering Copier)

3050 (Engineering Copier)

3060 (Engineering Copier)

3100 (Antique Copier)

3100LDC

3100 (Versant 3100)

3107 (Antique Copier)

3109 (Antique Copier)

3116 (Phaser 3116)

3120 (Phaser 3120)

3121 (Phaser 3121)

3130 (Phaser 3130)

3150 (Phaser 3150)

3200 (Phaser 3200MFP)

3210 (WorkCentre 3210)

3215 (WorkCentre 3215)

3220 (WorkCentre 3220)

3225 (DocuPrint N3225)

3225(WorkCentre 3225)

3250 (Phaser 3250)

3300 (Phaser 3300MFP)

3315 (WorkCentre 3315)

3320 (Phaser 3320)

3325 (WorkCentre 3325)

3335(WorkCentre 3335)

3345(WorkCentre 3345)

3400 (Antique Copier)

3450 (Antique Copier)

3450 (Phaser 3450)

3500 (Phaser 3500)

3535 (DocuColor 3535)

3545 (C3545)

3550 (WorkCentre 3550)

3600 (Phaser 3600)

3610 (Phaser 3610)

3615 (WorkCentre 3615)

3635 (Phaser 3635MFP)

3655 (WorkCentre 3655)

4010 (Vintage Analog Copier)

4011 (Vintage Analog Copier)

4025 (DocuPrint N4025)

4110 (WorkCentre 4110)

4112 (WorkCentre 4112)

4118 (WorkCentre 4118)

4127 (WorkCentre 4127)

4150 (WorkCentre 4150)

4250 (WorkCentre 4250)

4260 (WorkCentre 4260)

4265 (WorkCentre 4265)

4400 (Phaser 4400)

4500 (Phaser 4500)

4510 (Phaser 4510)

4525 (DocuPrint N4525)

4590 (WorkCentre 4590)

4595 (WorkCentre 4590)

4600 (Phaser 4600)

4620 (Phaser 4620)

5000 (DocuColor 5000)

5008 (Vintage Analog Copier)

5008RE (Vintage Analog Copier)

5009 (Vintage Analog Copier)

5009RE (Vintage Analog Copier)

5011 (Vintage Analog Copier)

5012 (Vintage Analog Copier)

5014 (Vintage Analog Copier)

5016 (Vintage Analog Copier)

5016 (WorkCentre 5016)

5018 (Vintage Analog Copier)

5019 (WorkCentre 5019)

5020 (WorkCentre 5020)

5021 (Vintage Analog Copier)

5021 (WorkCentre 5021)

5022 (WorkCentre 5022)

5024 (WorkCentre 5024)

5028 (Vintage Analog Copier)

5030 (WorkCentre 5030)

5034 (Vintage Analog Copier)

5042 (Vintage Analog Copier)

5046 (Vintage Analog Copier)

5047 (Vintage Analog Copier)

5050 (Vintage Analog Copier)

5050 (WorkCentre 5050)

5051 (Vintage Analog Copier)

5052 (Vintage Analog Copier)

5053 (Vintage Analog Copier)

5065 (Vintage Analog Copier)

5100 (Vintage Analog Copier)

5113 (Vintage Analog Copier)

5114 (Vintage Analog Copier)

5126 (Vintage Analog Copier)

5135 (WorkCentre 5135)

5150 (WorkCentre 5150)

5201 (Vintage Compact Copier)

5203 (Vintage Compact Copier)

5205 (Vintage Compact Copier)

5208 (Vintage Analog Copier)

5210 (Vintage Compact Copier)

5220 (Vintage Compact Copier)

5222 (Vintage Compact Copier)

5222 (WorkCentre 5222)

5225 (WorkCentre 5225)

5230 (WorkCentre 5230)

5240 (Vintage Analog Copier)

5252 (DocuColor 5252)

5260 (Vintage Analog Copier)

5280 (Vintage Analog Copier)

5305 (Vintage Compact Copier)

5306 (Vintage Compact Copier)

5307 (Vintage Analog Copier)

5308 (Vintage Analog Copier)

5309 (Vintage Analog Copier)

5310 (Vintage Analog Copier)

5312 (Vintage Analog Copier)

5313 (Vintage Analog Copier)

5314 (Vintage Analog Copier)

5318 (Vintage Analog Copier)

5320 (Vintage Analog Copier)

5321 (Vintage Analog Copier)

5322 (Vintage Analog Copier)

5325 (WorkCentre 5325)

5328 (Vintage Analog Copier)

5330 (WorkCentre 5330)

5334 (Vintage Analog Copier)

5335 (Vintage Analog Copier)

5335 (Phaser 5335)

5335 (WorkCentre 5335)

5337 (Vintage Analog Copier)

5340 (Vintage Analog Copier)

5343 (Vintage Analog Copier)

5343c (Vintage Analog Copier)

5345 (Vintage Analog Copier)

5350 (Vintage Analog Copier)

5352 (Vintage Analog Copier)

5352c (Vintage Analog Copier)

5355 (Vintage Analog Copier)

5365 (Vintage Analog Copier)

5388 (Vintage Analog Copier)

5437 (Vintage Analog Copier)

5441 (Vintage Analog Copier)

5451 (Vintage Analog Copier)

5500 (Phaser 5500)

5550 (Phaser 5550)

5614 (Vintage Analog Copier)

5622 (Vintage Analog Copier)

5624 (Vintage Analog Copier)

5626 (Vintage Analog Copier)

5632 (WorkCentre 5632)

5638 (WorkCentre 5638)

5645 (WorkCentre 5645)

5655 (WorkCentre 5655)

5665 (Vintage Analog Copier)

5665 (WorkCentre 5655)

5675 (WorkCentre 5675)

5680 (Vintage Analog Copier)

5687 (WorkCentre 5687)

5735 (WorkCentre 5735)

5740 (WorkCentre 5740)

5745 (WorkCentre 5745)

5755 (WorkCentre 5755)

5760 (MajestiK - Vintage)

5765 (MajestiK - Vintage)

5765 (WorkCentre 5765)

5775 (WorkCentre 5775)

5790 (Regal - Vintage)

5790 (WorkCentre 5790)

5800 (Vintage Analog Copier)

5818 (Vintage Analog Copier)

5820 (Vintage Analog Copier)

5824 (Vintage Analog Copier)

5826 (Vintage Analog Copier)

5828 (Vintage Analog Copier)

5830 (Vintage Analog Copier)

5837 (Vintage Analog Copier)

5845 (Vintage Analog Copier)

5845 (WorkCentre 5845)

5855 (Vintage Analog Copier)

5855 (WorkCentre 5855)

5865 (WorkCentre 5865)

5875 (WorkCentre 5875)

5890 (Vintage Analog Copier)

5890 (WorkCentre 5890)

5892 (Vintage Copier)

5945 (WorkCentre 5945)

5955 (WorkCentre 5955)

6050 (Engineering)

6060 (DocuColor 6060)

6110 (Phaser 6110)

6110MFP (Phaser 6110MFP)

6115 (DocuTech 6115)

6120 (Phaser 6120)

6125 (Phaser 6125)

6130 (Phaser 6130)

6135 (DocuTech 6135)

6140 (Phaser 6140)

6155 (DocuTech 6155)

6180 (DocuTech 6180)

6180 (Phaser 6180)

6204 (Engineering Machine)

6250 (Phaser 6250)

6279 (Engineering Machine)

6280 (Phaser 6280)

6300 (Phaser 6300)

6350 (Phaser 6350)

6360 (Phaser 6360)

6400 (WorkCentre 6400)

6500 (Phaser 6500)

6505 (WorkCentre 6505)

6510 (Phaser 6510)

6515 (WorkCentre 6515)

6600 (Phaser 6600)

6605 (WorkCentre 6605)

6655 (WorkCentre 6655)

6700 (Phaser 6700)

7000 (DocuColor 7000)

7020 (VersaLink C7020)

7025 (VersaLink B7025)

7030 (B7030)

7030 (C7030)

7035 (B7035)

7041 (Vintage Fax Machine)

7042 (Vintage Fax Machine)

7120 (WorkCentre 7120)

7120 (VersaLink C7120)

7125 (WorkCentre 7125)

7125 (VersaLink B7125)

7125 (VersaLink C7125)

7130 (VersaLink B8130)

7130 (VersaLink C7130)

7132 (WorkCentre 7132)

7135 (VersaLink B7135)

7220 (WorkCentre 7220)

7225 (WorkCentre 7225)

7228 (WorkCentre 7228)

7232 (WorkCentre 7232)

7235 (WorkCentre 7235)

7242 (WorkCentre 7242)

7245 (WorkCentre 7245)

7328 (WorkCentre 7328)

7335 (WorkCentre 7335)

7345 (WorkCentre 7345)

7346 (WorkCentre 7346)

7400 (Phaser 7400)

7425 (WorkCentre 7425)

7428 (WorkCentre 7428)

7435 (WorkCentre 7435)

7500 (Phaser 7500)

7525 (WorkCentre 7525)

7530 (WorkCentre 7530)

7535 (WorkCentre 7535)

7545 (WorkCentre 7545)

7556 (WorkCentre 7556)

7655 (WorkCentre 7655)

7665 (WorkCentre 7665)

7675 (WorkCentre 7675)

7700 (Phaser 7700)

7750 (Phaser 7750)

7755 (WorkCentre 7755)

7760 (Phaser 7760)

7765 (WorkCentre 7765)

7775 (WorkCentre 7775)

7800 (Phaser 7800)

7830 (WorkCentre 7830)

7835 (WorkCentre 7835)

7845 (WorkCentre 7845)

7855 (WorkCentre 7855)

7970 (WorkCentre 7970)

8000 (DocuColor 8000)

8030 (C8030)

8035 (C8035)

8045 (C8045)

8045

8055 (C8055)

8055

8065

8070 (C8070)

8075

8090

8090

8265 (Vintage Copier)

8290 (Vintage Copier)

8825 (Engineering Printer)

8830 (Engineering Printer)

8850 (Engineering Machine)

9065(C9065)YY

9070(C9070)

9100(B9100)

9110(B9110)

9125(B9125)

9136(B9136)

AltaLink B8045

AltaLink B8055

AltaLink B8065

AltaLink B8075

AltaLink B8090

AltaLink C8030

AltaLink C8035

AltaLink C8045

AltaLink C8055

AltaLink C8070

B-8045

B-8055

B-8065

B-8075

B-8090

B400 (VersaLink B400)

B405 (VersaLink B405)

B600 (VersaLink B600)

B605 (VersaLink B605)

B610 (VersaLink B610)

B615 (VersaLink B615)

B8045

B8055

B8065

B8075

B8090

Bookmark 55

Bookmark 21

Bookmark 35

Bookmark 40

C400 (VersaLink C400)

C405 (VersaLink C405)

C500 (VersaLink C500)

C-500 (VL-C500)

C505 (VersaLink C505)

C-505 (VL-C505)

VersaLink C600

C600 (VersaLink C600)

C-600 (VL-C600)

VersaLink C605

C605 (VersaLink C605)

C-605 (VL-C605)

VersaLink C7000

C7000 (VersaLink)

C7020 (VersaLink)

C7025 (VersaLink)

C7030 (VersaLink)

C20 (CopyCentre C20)

C32

C35 (CopyCentre C35)

C40

C45 (CopyCentre C45)

C55 (CopyCentre C55)

C60 (Color C60)

C65 (CopyCentre C65)

C70 (Color C70)

C75 (Color C75 Press)

C75 (CopyCentre C75)

C118 (CopyCentre C118)

C123 (CopyCentre C123

C128 (CopyCentre C128)

C133 (CopyCentre C133)

C550 (Color 550)

C560 (Color 560)

C2128

C2636

C3545

Color 560

Color 570

Color C60

Color C70

Color C75 Press

Color J75 Press

CopyCentre 165

CopyCentre 175

CopyCentre 232

CopyCentre 238

CopyCentre 245

CopyCentre 255

CopyCentre 265

CopyCentre 275

CopyCentre C20

CopyCentre C35

CopyCentre C45

CopyCentre C55

CopyCentre C65

CopyCentre C75

CopyCentre C90

CopyCentre C90

CopyCentre C118

CopyCentre C123

CopyCentre C133

CopyCentre C2128

D95 (D95A)

D110

D125

D136

DC-4 (DocuColor 4)

DC12 (DocuColor 12)

DC212 (DocumentCentre 212)

DC214 (DocumentCentre 214)

DC220 (DocumentCentre 220)

DC230 (DocumentCentre 230)

DC-240 (DocuColor 240)

DC-240 (DocumentCentre 240)

DC-242 (DocuColor 242)

DC-250 (DocuColor 250)

DC-252 (DocuColor 252)

DC-255 (DocumentCentre 255)

DC-260 (DocuColor 260)

DC-265 (DocumentCentre 265)

DC-332 (DocumentCentre 332)

DC-340 (DocumentCentre 340)

DC-420 (DocumentCentre 420)

DC-425 (DocumentCentre 425)

DC-426 (DocumentCentre 426)

DC-430 (DocumentCentre 430)

DC-432 (DocumentCentre 432)

DC-440 (DocumentCentre 440)

DC-460 (DocumentCentre 460)

DC-470 (DocumentCentre 470)

DC-480 (DocumentCentre 480)

DC-490 (DocumentCentre 490)

DC-535 (DocumentCentre 535)

DC-545 (DocumentCentre 545)

DC-555 (DocumentCentre 555)

DC1632 (DocuColor 1632)

DC2006 (DocuColor 2006)

DC2045 (DocuColor 2045)

DC2060 (DocuColor 2060)

DC2240 (DocuColor 2240)

DC-3535 (DocuColor 3535)

DC-5000 (DocuColor 5000)

DC-5252 (DocuColor 5252)

DC-6060 (DocuColor 6060)

DC-7000 (DocuColor 7000)

DC-8000 (DocuColor 8000)

DCCS-50

DCP-700i (Digital Color Press 700i)

DCP-770 (Digital Color Press 770)

DCP-700 (Digital Color Press 700)

DocuPrint 65

DocuPrint 75

DocuPrint 90

DocuPrint N24

DocuPrint N32

DocuPrint N40

DocuPrint N3225

DocuPrint N4025

DocuPrint N4525

DocuPrint P8

DocuTech 65

DocuTech 75

DocuTech 90

DocuTech 128

DocuTech 135

DocuTech 155

DocuTech 180

DocuTech 6115

DocuTech 6135

DocuTech 6155

DocuTech 6180

DT-100 (DocuTech 100)

DT-120 (DocuTech 120)

EPS-4110

EPS-4112

EPS-4127

EPS-4590

EPS-4595

FaxCentre 2218

FaxCentre F12

J75 Press

M15 (WorkCentre M15)

M-15 (WorkCentre M15)

M-15i (WorkCentre M15i)

M15i (WorkCentre M15i)

M20 (WorkCentre M20)

M-20 (WorkCentre M20)

M-20i (WorkCentre M20i)

M20i (WorkCentre M20i)

M24 (WorkCentre M24)

M-24 (WorkCentre M24)

M-35 (WorkCentre M35)

M35 (WorkCentre M35)

M45 (WorkCentre M45)

M-45 (WorkCentre M45)

M-55 (WorkCentre M55)

M55 (WorkCentre M55)

M118 (WorkCentre M118)

M-118 (WorkCentre M118)

M-118i (WorkCentre M118i)

M118i (WorkCentre M118i)

M123 (WorkCentre M123)

M-123 (WorkCentre M123)

M-128 (WorkCentre M128)

M128 (WorkCentre M128)

M133 (WorkCentre M133)

M-133 (WorkCentre M133)

M-165 (WorkCentre M165)

M165 (WorkCentre M165)

M175 (WorkCentre M175)

M-175 (WorkCentre M175)

N-24 (DocuPrint N24)

N24 (DocuPrint N24)

N32 (DocuPrint N32)

N-32 (DocuPrint N32)

N-40 (DocuPrint N40)

N40 (DocuPrint N40)

N-4025 (DocuPrint N4025)

N4025 (DocuPrint N4025)

N4525 (DocuPrint N4525)

N-4525 (DocuPrint N4525)

Nuvera 100

Nuvera 120

Nuvera 144

Nuvera 200

Nuvera 288

P8 (DocuPrint P8)

P-8 (DocuPrint P8)

PE-16 (WorkCentre PE16)

PE16 (WorkCentre PE16)

PE16i (WorkCentre PE16i)

PE-16i (WorkCentre PE16i)

PE-120 (WorkCentre PE120)

PE120 (WorkCentre PE120)

PE120i (WorkCentre PE120i)

PE-120i (WorkCentre PE120i)

Phaser 780

Phaser 790

Phaser 3116

Phaser 3120

Phaser 3121

Phaser 3130

Phaser 3150

Phaser 3200MFP

Phaser 3250

Phaser 3300MFP

Phaser 3320

Phaser 3450

Phaser 3500

Phaser 3600

Phaser 3610

Phaser 3635MFP

Phaser 4400

Phaser 4500

Phaser 4510

Phaser 4600

Phaser 4620

Phaser 5335

Phaser 5500

Phaser 5550

Phaser 6110

Phaser 6110MFP

Phaser 6120

Phaser 6125

Phaser 6130

Phaser 6140

Phaser 6180

Phaser 6250

Phaser 6280

Phaser 6300

Phaser 6350

Phaser 6360

Phaser 6500

Phaser 6600

Phaser 6700

Phaser 7400

Phaser 7500

Phaser 7700

Phaser 7750

Phaser 7760

Phaser 7800

Phaser 8500

Phaser 8550

Phaser 8560

Phaser 8860MFP

PrimeLinkC9065

PrimeLinkC9070

PrimeLinkB9100

PrimeLinkB9110

PrimeLinkB9125

PrimeLinkB9136

Pro-16 (WorkCentre Pro-16)

Pro-16fx (WorkCentre Pro-16fx)

Pro-16p (WorkCentre Pro-26p)

Pro-32 (WorkCentre Pro-32)

Pro-35 (WorkCentre Pro-35)

Pro-40 (WorkCentre Pro-40)

Pro-45 (WorkCentre Pro-45)

Pro-55 (WorkCentre Pro-55)

Pro-65 (WorkCentre Pro-65)

Pro-75 (WorkCentre Pro-75)

Pro-90 (WorkCentre Pro-90)

Pro-123 (WorkCentre Pro-123)

Pro-128 (WorkCentre Pro 128)

Pro-133 (WorkCentre Pro 133)

Pro-165 (WorkCentre Pro-165)

Pro-175 (WorkCentre Pro-175)

Pro-215 (DocumentCentre)

Pro-275 (WorkCentre Pro-275)

Pro-315 (WorkCentre Pro-315)

Pro-412 (WorkCentre Pro-412)

Pro-415 (WorkCentre Pro-415)

Pro-416 (WorkCentre Pro-416)

Pro-420 (WorkCentre Pro-420)

Pro-421 (WorkCentre Pro-421)

Pro-423 (WorkCentre Pro-423)

Pro-428 (WorkCentre Pro-428)

Pro-535 (Vintage Fax Machine)

Pro-545 (Vintage Fax Machine)

Pro-635 (WorkCentre Pro-635)

Pro-645 (WorkCentre Pro-645)

Pro-657 (WorkCentre Pro-657)

Pro-665 (WorkCentre Pro-665)

Pro-685 (WorkCentre Pro-685)

Pro-735 (WorkCentre Pro-735)

Pro-745 (WorkCentre Pro-745)

Pro-765 (WorkCentre Pro-765)

Pro-785 (WorkCentre Pro-785)

Pro-C2128

Pro-C2636

Pro-C3545

V-80 (V80)

V-180 (V180)

V-2100 (V2100)

V-3100 (V3100)

VersaLink C7020

VersaLink B7025

VersaLink C7025

VersaLink C7030

VersaLink B7030

VersaLink B7035

VersaLink C7120

VersaLink C7120

VersaLink B7125

VersaLink C7125

VersaLink B7130

VersaLink C7130

VersaLink B7135

VersaLink B400

VersaLink B405

VersaLink B600

VersaLink B605

VersaLink B610

VersaLink B615

VersaLink C400

VersaLink C405

VersaLink C500

VersaLink C505

VersaLink C7020

VersaLink C7025

VersaLink C7025

VersaLink C7025

Versant 2100

WC-165

WC-175

WC-232

WC-238

WC-245

WC-255

WC-265

WC-275

WC-312

WC-385

WC-395

WC-3210

WC-3220

WC-3315

WC-3325

WC-3550

WC-3615

WC-3655

WC-4110

WC-4112

WC-4118

WC-4127

WC-4150

WC-4250

WC-4260

WC-4265

WC-4590

WC-4595

WC-5016

WC-5019

WC-5020

WC-5021

WC-5022

WC-5024

WC-5030

WC-5050

WC-5135

WC-5150

WC-5222

WC-5225

WC-5230

WC-5325

WC-5330

WC-5335

WC-5632

WC-5638

WC-5645

WC-5655

WC-5665

WC-5675

WC-5687

WC-5735

WC-5740

WC-5745

WC-5755

WC-5765

WC-5775

WC-5790

WC-5840

WC-5845

WC-5855

WC-5865

WC-5875

WC-5890

WC-5945

WC-5955

WC-6400

WC-6505

WC-6605

WC-6655

WC-7120

WC-7125

WC-7132

WC-7220

WC-7225

WC-7228

WC-7232

WC-7235

WC-7242

WC-7245

WC-7328

WC-7335

WC-7345

WC-7346

WC-7425

WC-7428

WC-7435

WC-7525

WC-7530

WC-7535

WC-7545

WC-7556

WC-7655

WC-7665

WC-7675

WC-7755

WC-7765

WC-7775

WC-7830

WC-7835

WC-7845

WC-7855

WC-7970

WC-Bookmark 40

WC-Bookmark 40

WC-Bookmark 55

WC-C2128

WC-M15

WC-M15i

WC-M20

WC-M20i

WC-M24

WC-M35

WC-M45

WC-M55

WC-M118

WC-M123

WC-M128

WC-M133

WC-M165

WC-M175

WC-PE16

WC-PE16i

WC-PE120

WC-PE120i

WC-Pro16

WC-Pro16fx

WC-Pro16p

WC-Pro35

WC-Pro45

WC-Pro55

WC-Pro65

WC-Pro75

WC-Pro90

WC-Pro123

WC-Pro128

WC-Pro133

WC-Pro165

WC-Pro175

WC-Pro215

WC-Pro275

WC-Pro315

WC-Pro412

WC-Pro415

WC-Pro416

WC-Pro420

WC-Pro421

WC-Pro423

WC-Pro428

WC-Pro535

WC-Pro545

WC-Pro635

WC-Pro645

WC-Pro657

WC-Pro665

WC-Pro685

WC-Pro735

WC-Pro745

WC-Pro765

WC-Pro785

WC-Pro-C2128

WC-Pro-C2636

WC-Pro-C3545

WC-XD102

WC-XD103

WC-XD103f

WC-XD104

WC-XD105

WC-XD105f

WC-XD120

WC-XD120f

WC-XD125

WC-XD125f

WC-XD130

WC-XD130df

WC-XD155

WC-XD155df

WC-XD100

WC-XE62

WC-XE64

WC-XE80

WC-XE82

WC-XE84

WC-XE88

WC-XE90

WC-XE90fx

WC-XE60

WC-XL2120

WC-XL2130

WC-XL2130f

WC-XL2140

WC-XL2140df

WC-6515

WorkCentre 165

WorkCentre 175

WorkCentre 232

WorkCentre 238

WorkCentre 245

WorkCentre 255

WorkCentre 265

WorkCentre 275

WorkCentre 312

WorkCentre 385

WorkCentre 395

WorkCentre 3210

WorkCentre 3220

WorkCentre 3315

WorkCentre 3325

WorkCentre 3550

WorkCentre 3615

WorkCentre 3655

WorkCentre 4110

WorkCentre 4112

WorkCentre 4118

WorkCentre 4127

WorkCentre 4150

WorkCentre 4250

WorkCentre 4260

WorkCentre 4265

WorkCentre 4590

WorkCentre 4595

WorkCentre 5016

WorkCentre 5019

WorkCentre 5020

WorkCentre 5021

WorkCentre 5022

WorkCentre 5024

WorkCentre 5030

WorkCentre 5050

WorkCentre 5135

WorkCentre 5150

WorkCentre 5222

WorkCentre 5225

WorkCentre 5230

WorkCentre 5325

WorkCentre 5330

WorkCentre 5335

WorkCentre 5632

WorkCentre 5638

WorkCentre 5645

WorkCentre 5655

WorkCentre 5665

WorkCentre 5675

WorkCentre 5687

WorkCentre 5735

WorkCentre 5740

WorkCentre 5745

WorkCentre 5755

WorkCentre 5765

WorkCentre 5775

WorkCentre 5790

WorkCentre 5840

WorkCentre 5845

WorkCentre 5855

WorkCentre 5865

WorkCentre 5875

WorkCentre 5890

WorkCentre 5945

WorkCentre 5955

WorkCentre 6400

WorkCentre 6505

WorkCentre 6605

WorkCentre 6655

WorkCentre 7120

WorkCentre 7125

WorkCentre 7132

WorkCentre 7220

WorkCentre 7225

WorkCentre 7228

WorkCentre 7232

WorkCentre 7235

WorkCentre 7242

WorkCentre 7245

WorkCentre 7328

WorkCentre 7335

WorkCentre 7345

WorkCentre 7346

WorkCentre 7425

WorkCentre 7428

WorkCentre 7435

WorkCentre 7525

WorkCentre 7530

WorkCentre 7535

WorkCentre 7545

WorkCentre 7556

WorkCentre 7655

WorkCentre 7665

WorkCentre 7675

WorkCentre 7755

WorkCentre 7765

WorkCentre 7775

WorkCentre 7830

WorkCentre 7835

WorkCentre 7845

WorkCentre 7855

WorkCentre 7970

WorkCentre Bookmark 40

WorkCentre Bookmark 40

WorkCentre Bookmark 55

WorkCentre C2128

WorkCentre M15

WorkCentre M15i

WorkCentre M20

WorkCentre M20i

WorkCentre M24

WorkCentre M35

WorkCentre M45

WorkCentre M55

WorkCentre M118

WorkCentre M123

WorkCentre M128

WorkCentre M133

WorkCentre M165

WorkCentre M175

WorkCentre PE16

WorkCentre PE16i

WorkCentre PE120

WorkCentre PE120i

WorkCentre Pro16

WorkCentre Pro16fx

WorkCentre Pro16p

WorkCentre Pro35

WorkCentre Pro45

WorkCentre Pro55

WorkCentre Pro65

WorkCentre Pro75

WorkCentre Pro90

WorkCentre Pro123

WorkCentre Pro128

WorkCentre Pro133

WorkCentre Pro165

WorkCentre Pro175

WorkCentre Pro215

WorkCentre Pro275

WorkCentre Pro315

WorkCentre Pro412

WorkCentre Pro415

WorkCentre Pro416

WorkCentre Pro420

WorkCentre Pro421

WorkCentre Pro423

WorkCentre Pro428

WorkCentre Pro535

WorkCentre Pro545

WorkCentre Pro635

WorkCentre Pro645

WorkCentre Pro657

WorkCentre Pro665

WorkCentre Pro685

WorkCentre Pro735

WorkCentre Pro745

WorkCentre Pro765

WorkCentre Pro785

WorkCentre Pro-C2128

WorkCentre Pro-C2636

WorkCentre Pro-C3545

WorkCentre XD102

WorkCentre XD103

WorkCentre XD103f

WorkCentre XD104

WorkCentre XD105

WorkCentre XD105f

WorkCentre XD120

WorkCentre XD120f

WorkCentre XD125

WorkCentre XD125f

WorkCentre XD130

WorkCentre XD130df

WorkCentre XD155

WorkCentre XD155df

WorkCentre XE60

WorkCentre XE62

WorkCentre XE64

WorkCentre XE80

WorkCentre XE82

WorkCentre XE84

WorkCentre XE88

WorkCentre XE90

WorkCentre XE90fx

WorkCentre XL2120

WorkCentre XL2130

WorkCentre XL2130f

WorkCentre XL2140

WorkCentre XL2140df

XC23

XC33

XC33D

XC351

XC355

XC356

XC520

XC-550 (Color 550)

XC-560 (Color 560)

XC-570 (Color 570)

XC580 (Vintage Compact Copier)

XC810

XC811

XC820

XC830

XC855

XC865

XC875

XC1020

XC1033

XC1040

XC1044

XC1045

XC1245

XC1250

XC1255

XC1875

XC2675

XC-C60 (Color C60)

XC-C70 (Color C70)

XC560 (Vintage Compact Copier)

XD100 (WorkCentre XD100)

XD102

XD103

XD103f

XD104

XD105

XD105f

XD120

XD120f

XD125

XD125f

XD130

XD130df

XD155

XD155df

XDL23

XDL33

XDL33D

XL2120

XL2130

XL2130f

XL2140

XL2140df