Important: The information presented here is for the use of a qualified, experienced technician. Without the background knowledge which comes with training, you risk doing more damage then good to the copier & also risk your own safety. If you are not willing to take 100% responsibility for your actions, do not use the information posted here. Thank you. Read our conditions of Use for more information.

WC-3655 Fuser Module Rebuild Instructions

Rebuild the fusers for the WC-3655

| Technical Specifications |

|---|

Xerox® WC-3655/3615 & B405/B400 - Fuser Modules… Repairing and rebuilding the Fusers for the WorkCentre® 3655 / 3615, Phaser® 3600, & VersaLink® B405 / B400

Here is a group of machines worth mentioning due to the sheer volume of machines sold out into the field. It’s a great machine for being compact and relatively quick (especially the 55ppm 3655) and according to the word on the street, they’re reliable. Only complaint from folks is that they are not good for printing on envelopes. Already I digress! Today we will concentrate on rebuilding the Fuser Modules as some really good aftermarket Heat Rolls and Pressure Sleeves are now available.

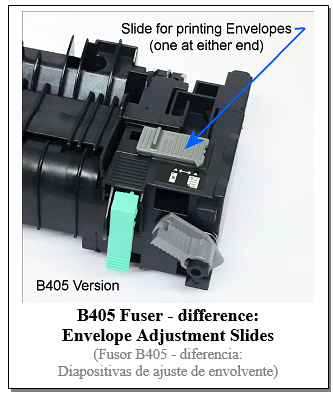

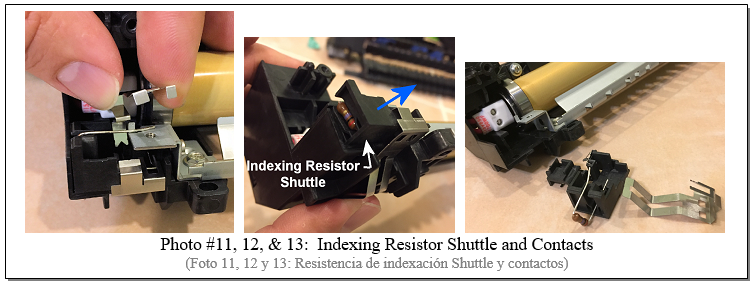

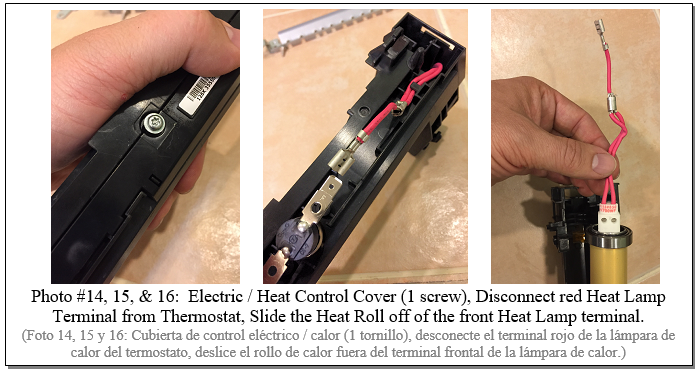

There are two versions in this series so far. First came the 3655FA Fusers for the WC-3655/3615 and Phaser 3610. These are usually sold in a Maintenance Kit along with the BTR Assembly (Transfer Roll): 115R00084 (115R84). Valid part numbers for the fusers alone would be: 126K30919, 126K35550 or 126K35551. The newest models to come out in the “3655 Style” are the VersaLink® B405 and B400. These have an extremely similar fuser. The Heat Roll, Pressure Sleeve and most other parts interchange nicely, but the fuser itself is not interchangeable. The B405 fuser also usually sells in a Maintenance Kit (115R00119), although again there are a few valid part numbers for the fuser alone: 126K36841, 859K00950 or 126K36840. One thing which differentiates the two fusers is an indexing resistor on-board which has different ratings which the machine will recognize as being for the “correct” fuser. The other obvious difference is that on the B405 / B400 fuser, they included a new feature. They added two little gray sliding pieces (one near the top front and one near the top rear). These are designed to change the pressure in the fuser to help it handle envelopes better. This addresses the problems with envelope printing, but it is a rather impractical fix. If the customer wants to run envelopes, they need to stop the machine… allow it to cool for a while, turn the machine around and open the back door to access the fuser. They then slide the two little gray slide- pieces to the Envelope position. When done with envelopes, they need to remember to return the slides to the regular paper position. This type of fuser has a typical Heat Roller and a Pressure Sleeve which slips over a core with a fabric-like Slip Sheet inside, and a pair of oil wicks / pads. They should have enough Slip Sheet Lube inside to make it turn with as little friction as possible. Good lubricant in there may well turn out to be the most important key to getting good longevity out of your rebuilt fusers.

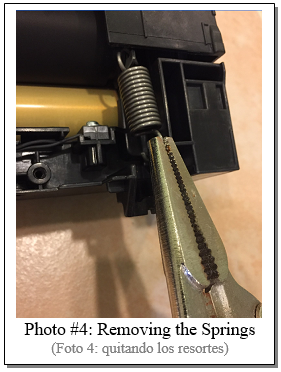

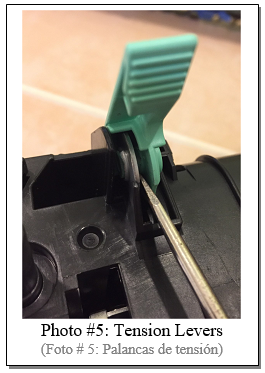

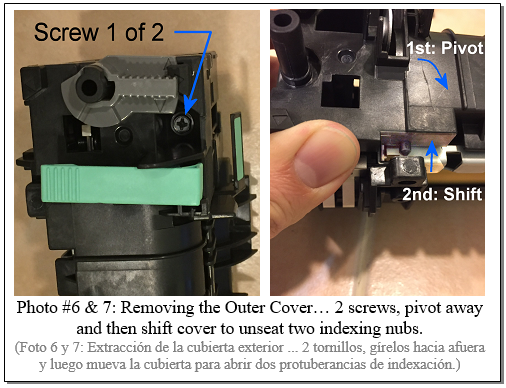

TOOLS NEEDED: - #2 Philips Head Screwdriver - T-10 Safety Torx Driver (or bit) - Needle-nosed Vice-Grip Pliers

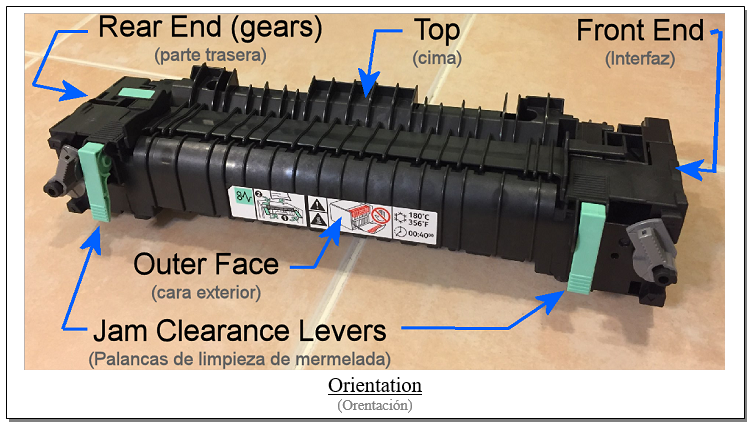

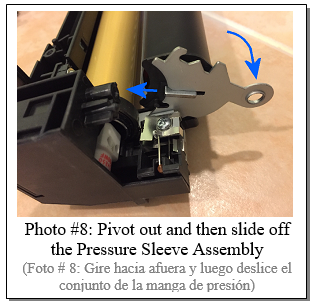

PARTS YOU MAY NEED: - Fuser Heat Roller (3655FHR) - Fuser Pressure Sleeve (3655FPS) - Fuser Heat Roll Bushings (heat sleeves) (3655FHS) & Bearings (3655FHRB) - Pressure Sleeve Lubricant (PSL) Let’s begin by getting oriented so we are all on the same page as to top vs. bottom, front vs. rear, and inner face vs. outer face. (see Photo #1)

REBUILD PROCEDURE:

Nice work! You just saved your customer a bit of green while keeping a perfectly good piece of equipment out of a landfill.

Resetting the Fuser Counter: For WC-3615 / WC-3655: 1. Press the “Machine Status” button. 2. Touch the “Tools” tab. 3. Next touch “Admin Settings” followed by “Service Tools”. 4. Touch “Reset Transfer Unit / Fuser”, followed by “Reset”. 6. Finally press “Yes, Reset”. For WC-3655 (for this model you need to first login as administrator: 1. Press “Login/Logout” and enter the username (default is ‘admin’) and then the password on the next screen (default is ‘1111’). 2. Press the “Machine Status” button. 3. Next touch the “Supplies” tab. 4. Then touch “Supply Counter Reset”, followed by “Reset CRU Life”. 6. Finally press “Reset Counter”.

For VersaLink B405 / B400: 1. Press the “Home” button. 2. Choose “Maintenance’ (gears icon). 3. Touch “Supplies”. 4. Touch “Maintenance Kit”. 5. Press “Reset”, followed by “Confirm”, and then “Close out”.

|

| Information Reference |

Author: Britt Horvat, with special thanks to Kurt for his expertise and thanks also for support from whole Partsdrop gang. Originally published as an Article in the marvelous ENX Magazine - www.enxmag.com :) All rights reserved... you can distribute copies as long as you include a link to the source website: www.partsdrop.com |